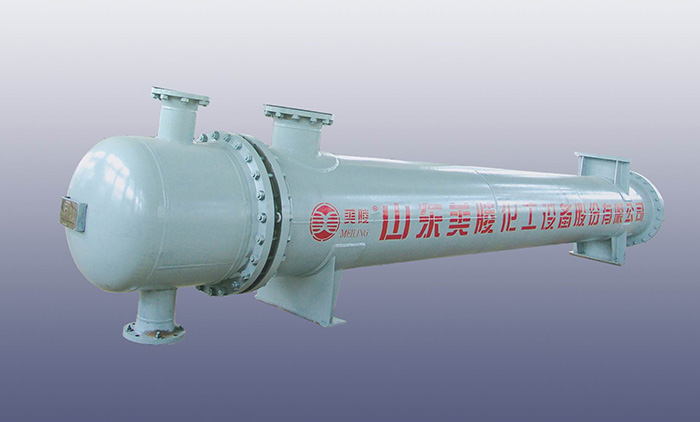

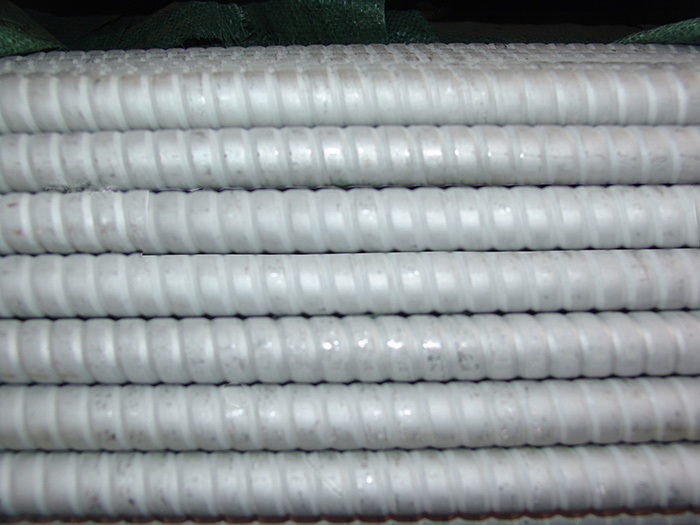

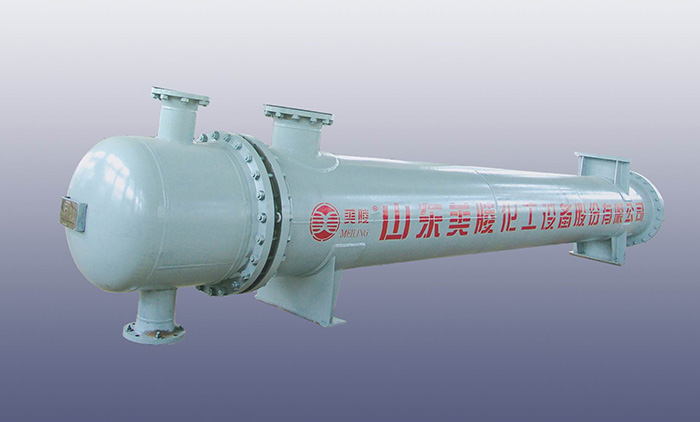

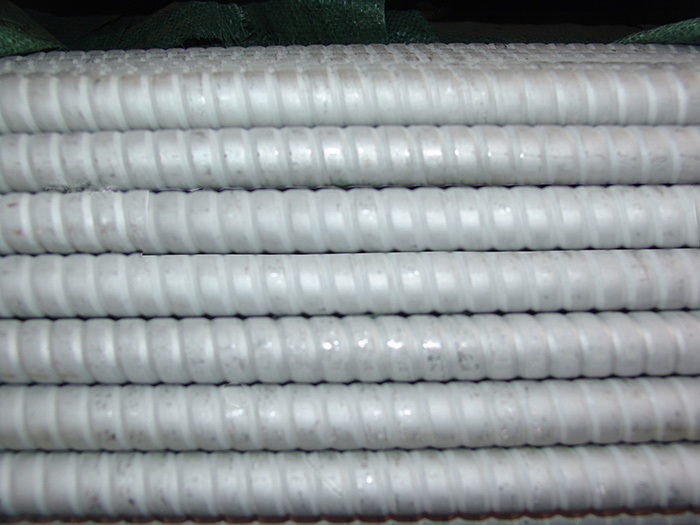

Bellows heat exchanger is a new type of shell-and-tube heat exchanger. The heat exchange tubes adopt bellows heat exchange bundles to replace the original smooth straight tubes. This heat exchanger increases the heat transfer efficiency by 2 to 4 times. The structure of the corrugated heat exchange tube changes periodically. The periodic changes are much more complicated than the smooth straight tube. This characteristic has a sufficient disturbance effect on the fluid in the tube, forcing the turbulent flow of the fluid, and increasing the heat transfer capacity of the heat exchange tube. The other advantage of the corrugated heat exchange tube is that the continuously shrinking and expanding tube shape makes the corrugated tube have the ability to compensate. That is, under the action of stress, the bellows heat exchange bundle can freely expand and contract in a certain range, and will not damage the heat exchanger tube plate and other components. At the same time, it is precisely this small "expansion" that makes the bellows heat exchanger bundle have a strong anti-scaling ability, so that the bellows tube heat exchanger has been widely used in industrial production.

Corrugated heat exchange tubes are generally made from seamless stainless steel tubes by secondary processing. Its longitudinal section is a continuous corrugation formed by the tangent of arcs of different radii. Hydraulic expansion type and soft rubber expansion type are the two main forming methods of corrugated heat exchange tube.

Advantages of bellows:

1. High heat transfer coefficient.

2. Can withstand low and medium pressure, have strong corrosion resistance and long service life.

3. Can adapt to larger temperature differences.

4. Can prevent and remove scale.

Heat exchange tube material: 10#, stainless steel, duplex stainless steel, 08Cr2AlMo.

|