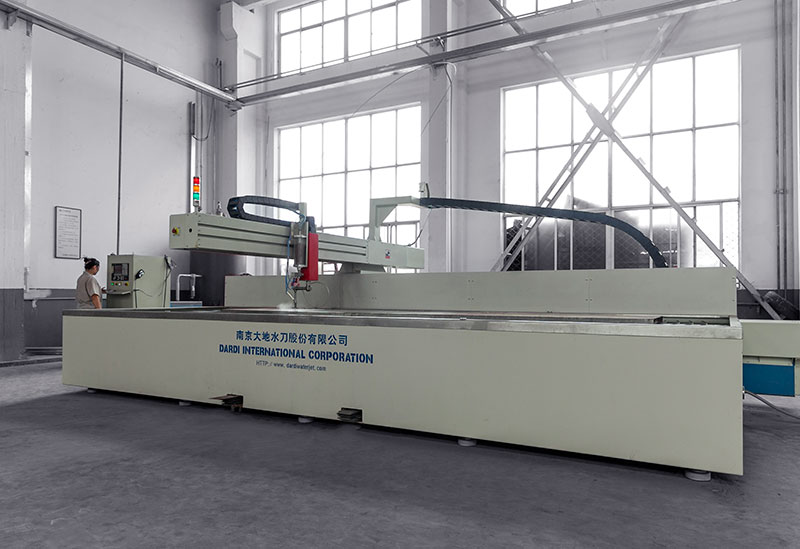

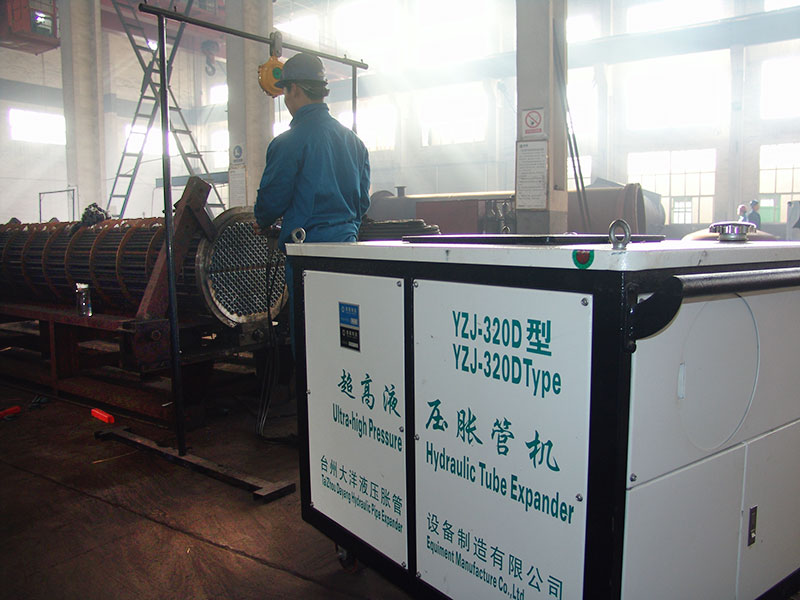

At present, our company's pressure vessel manufacturing capacity has reached 20,000 tons per year, has various equipment such as high-speed CNC drilling machines, CNC double-column vertical lathes, double-column vertical lathes, CNC machining centers, Zhongjie CNC drilling machines, large gantry milling machines, high-power laser cutting machines , high-power water cutting machine, 300-ton gantry crane, 180mm coil thickness CNC coiling machine, tube sheet automatic argon arc welding machine, French-made deep-hole welding machine, narrow gap welding complete equipment, saddle automatic hole-opening equipment, pipe connection ring seam automatic welding equipment, belt surfacing welding machine, hydraulic tube expansion machine, hydraulic automatic tube bending machine, large heat treatment furnace, tube sheet end heat treatment furnace, CNC cutting machine, CNC ring rolling machine, 5 tons, 3 ton and 1 ton electro-hydraulic free forging hammer, 5-ton discharge machine and other equipment, and can complete the blanking, coiling, welding, non-destructive testing, heat treatment, forging, machining and other processes of pressure vessel manufacturing. The main materials of the products manufactured by the company include: carbon steel, ordinary low alloy steel, Cr-Mo steel, austenitic stainless steel, duplex stainless steel, titanium, nickel, zirconium, copper, etc. The company has manufactured more than 12,000 energy-efficient heaters, and the largest diameter of the heat exchanger manufactured by the company is Φ4000mm, and the single weight is 220 tons.